MultiSeal Special

Where MultiSeal Standard or the MultiSeal set of lips are not first choice because of special installation reasons, TEDIMA offers still further solutions. The configuration of single and double-lip are dimensionally standardized and represent an economic seal for special solutions.

MultiSeal Special is available in several other materials than the standard ones.

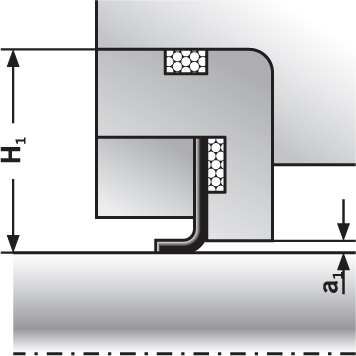

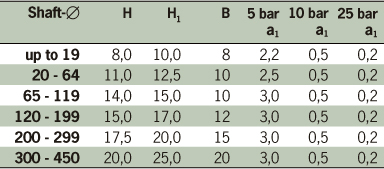

MultiSeal Special, single lip

|

|

|

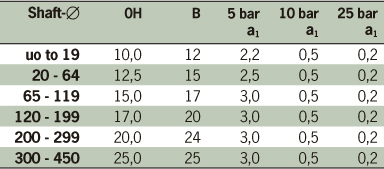

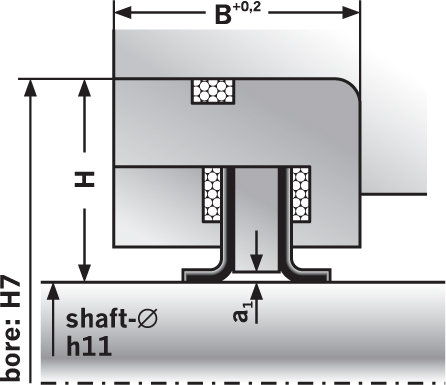

Order example for shaft-

|

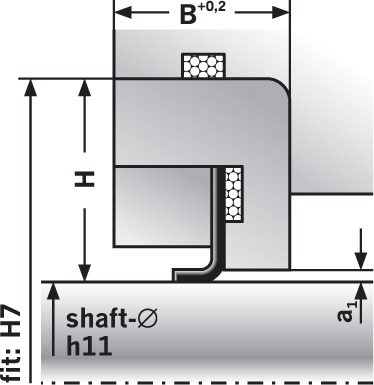

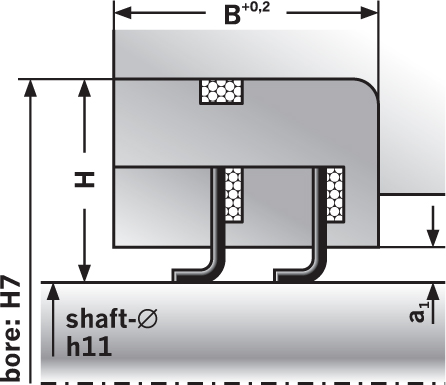

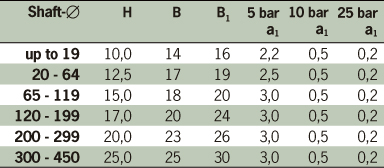

MultiSeal Special, double lip

|

|

|

| version up to 5 bar | version up to 25 bar |

|

Order example for shaft -Ø 80; 10 bar: TEDIMA MultiSeal Special, double lip tandem 80 × 110 × 20, 10 bar with O-ring |

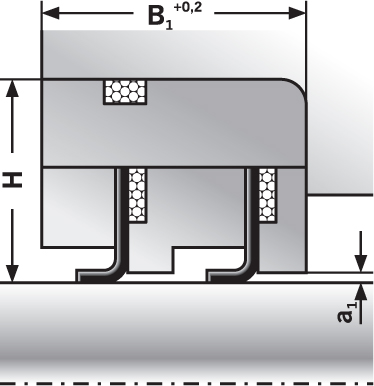

MultiSeal Special, double lip

|

Order example for shaft- |

|

| pressure/vaccum |

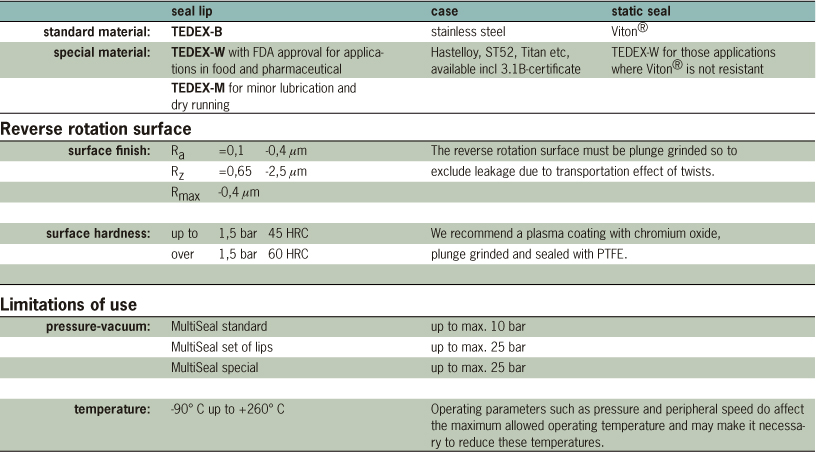

MultiSeal Special Technical Data

Materials

The seal lip material TEDEX – an especially modified PTFE-material – is the most important basis for the Double lip Double lip tandem Double lip outer seal successful application in MultiSeal high-performance seals.

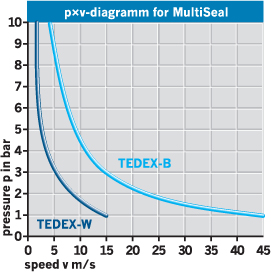

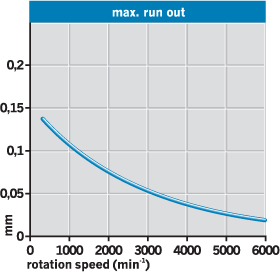

Several simultaneous operating parameters such as pressure and peripheral speed make it necessary to check the limitations of use. The below p×v diagram shows these limitations for TEDEX-B and TEDEX-W. The p×v values are based on full lubrication at an operating temperature of approximately 100°C and for all MultiSeal models up to 10 bar pressure.

Depending on the particular conditions, minor lubrication and dry running make it necessary to considerably reduce the mentioned values and need a coated reverse rotation surface. In such cases we strongly recommend to consult our specialists.

When applying a seal lip, minor friction loss is to be considered.

|

|

|

||

|

|

Русский

Русский

English

English

Deutsch

Deutsch

Español

Español

Italiana

Italiana

Français

Français

Nederlands

Nederlands

中国

中国

日本人

日本人

한국어

한국어

שידניה

שידניה

Türk Dili

Türk Dili

Қазақ тілі

Қазақ тілі